You Know It Idles, But How Much Does It Idle??

As we talk with construction companies from across the country, most don't know how much their equipment idles. Some have an idea that their equipment idles too much. Others don't even suspect that idle is a problem for them. However, in 15 years of working in the industry and gathering company data, we see that most companies have idle times across their fleets that average above 50%.

Think about that just a minute -- all of your equipment could be idling 50% of its run hours. That's cutting the useful life of your equipment in half, escalating your PM costs, and costing you extra fuel and labor costs for unproductive equipment.

Let's take a look at how our customer tackled that very issue...

Customer Example

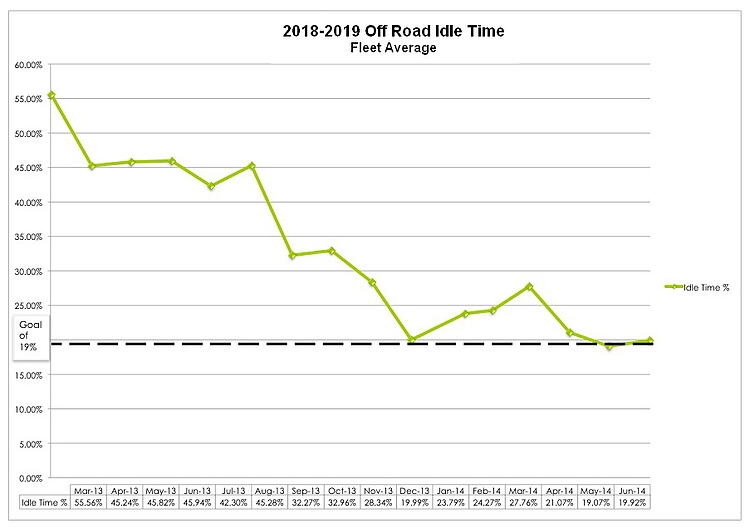

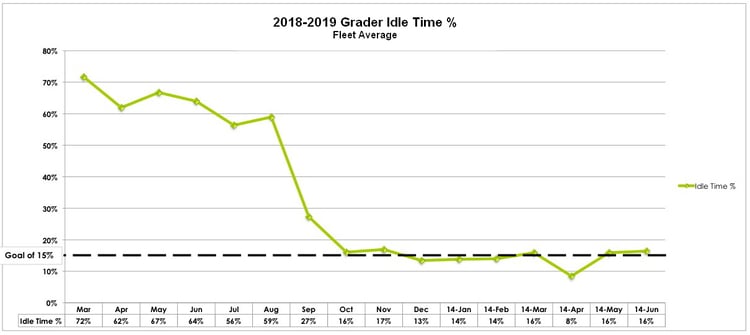

Earthwave signed on a new customer at the beginning of 2013, and completed installation in February of 2013. Within the first month, we recommend making no changes to the operations to get baseline on what's really happening. If you look at the charts below, our customer's Dozers idled 56% of the time and their Graders idled 72%.

In the second month, our customer begin using FleetWatcher's patented Escalating Idle Alerts to modify behavior in the field. What happened for them is what we see happening with all of our customers. Their idle times have dropped dramatically. Their Dozers are idling close to our recommended best practices rate of 19% and their Graders are idling very close to the 15% rate.

What if your equipment is idling at 56% or even 72%?

More importantly, what if you could reduce your idle to 15%, 19% or other Best Practices?

Let FleetWatcher Help You...

If you are looking for ways to improve your company's bottomline, then you've probably considered reducing the idle time of your equipment. The obvious savings are that you'll save on fuel and preventive maintenance costs. Other advantages can include extending the useful life of the equipment, lowering labor costs (because operators are working when equipment is running), reducing rental costs (because you'll get more use out of the equipment you own), and increasing revenues (lower costs and faster completion times allow you to bid more aggressively and win more jobs, all while operating more profitably).

If you'd like more info on FleetWatcher and the way that it can help you improve your company, click the links below to view the common problems that we solve or click the button to the right to schedule a live web demo.