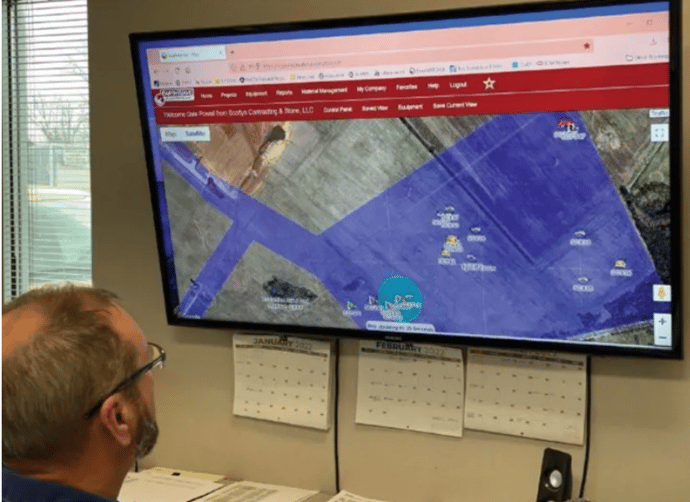

Some days running a business can feel like you’re treading water just to stay afloat. But on good days business leaders will have just enough bandwidth to manage their current day while planning for tomorrow. On days like this Walker Construction’s Scales/Truck Supervising Manager, Kevin Howard, is happy that his company has the telematic tools to prepare themselves to excel in tomorrow’s business climate.