When Robert Turner, fleet operations manager at RIPA & Associates, started using a telematics system in 2012, Caterpillar told him their tracks would last 4,000 hours. Apparently, that was total machine hours, running and idle—because the system quickly revealed that the average track was lasting 2,300 to 2,800 hours of run time.

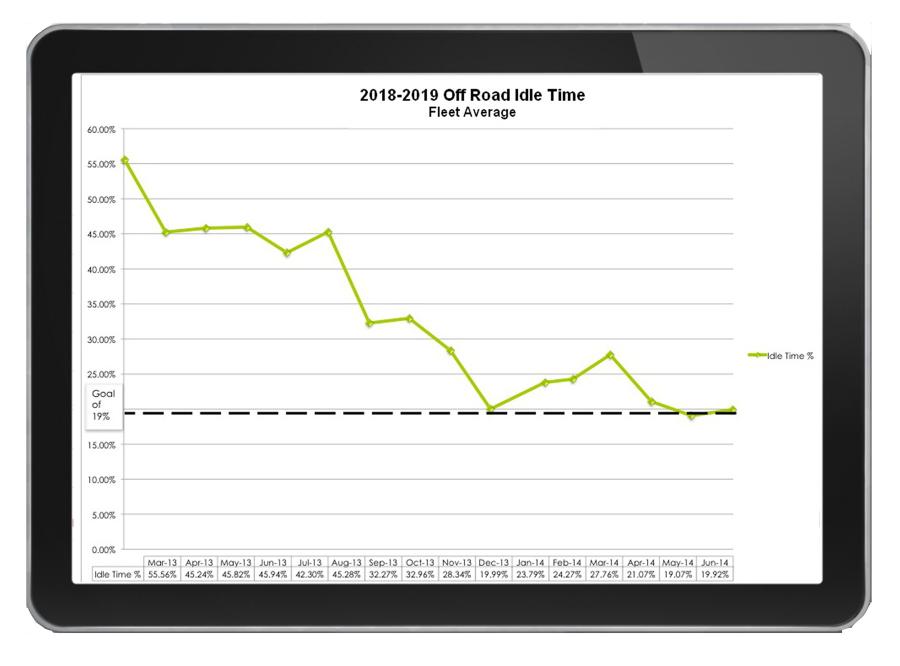

Although some of that differential can be attributed to the sandier, abrasive soil in Florida, the biggest reason was their elimination of idle time. The stark difference showed Turner the need to plan as a fleet department to keep the tracks running, so that idle time wouldn’t eat away the service life.

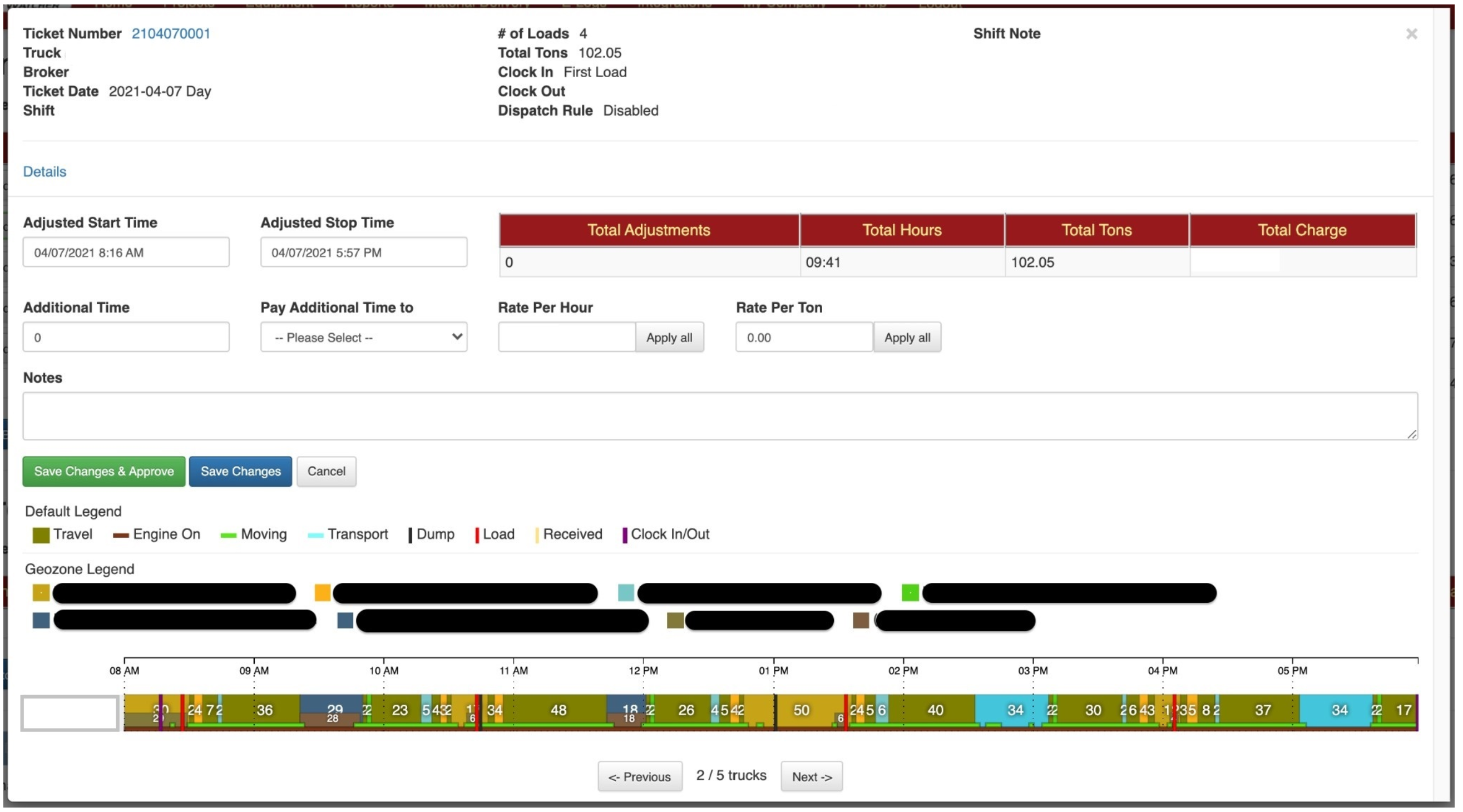

A breadcrumb trail shows Turner detailed location information for all machines in the field. Each time the unit updates (variable from 1- to 5-minute intervals), the packet shows the location of the machine and the reason for the packet (engine on, engine running, engine off, etc.). A GeoZone is provided to automatically track the machine’s activity within that GeoZone as well as when it arrives and leaves the GeoZone.

Now, Turner can plan out where machines go, what sites will need them next, and which machines can be leased out to keep their tracks moving and maximize their lifespan. The first year they used this telematics system, Turner estimates the company saved $1.3 million in preventative maintenance, resale value and fuel usage. Decreasing idle time for RIPA’s loaders alone saved them an estimated $400,000 for the year. The company achieved a radical reduction of idle time and a significant increase in overall productivity.

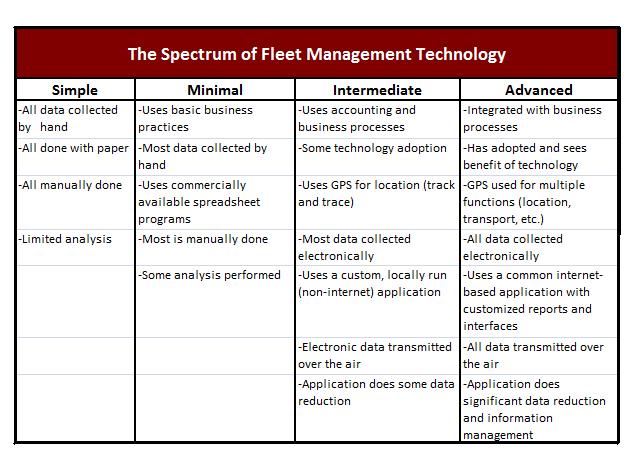

The RIPA team has become proficient in knowing how much gear is needed based on the size of the project, the distance and the type of project. Turner can now see what’s sitting on a jobsite that he knows should be moving and call up the foreman to see what’s going on. Turner put that savings into expanding the fleet, from 150 to over 1,000 transponder-enabled units in the field.

With so much equipment in the field working on projects across the region, Turner needs to be sure that he is giving accurate information to foremen and other contractors. His telematics system matches the machine number to information about that machine, keeping everything accurate and communicating that information to necessary parties.

Operators in the field can track equipment via mobile app, and Turner keeps an eye on things from his office. Checking in on equipment is simple, and Turner can rest easy knowing accurate information is accessible across all of the company’s jobsites. With easy-to-read, accessible information available at the touch of a screen, Turner can tell where every piece of RIPA equipment is in the field, what it’s doing and when it next needs maintenance. Rather than tracking that himself—a menial and laborious task that is prone to error—telematics tracks it all for him, allowing him to do the more advanced job of sending equipment where it’s needed next, and lining up contracts for the next project down the line. That allows Turner to manage his fleet more efficiently, preventing idle time, thwarting thieves and saving costly mistakes.

If you are interested is gaining visibility over your fleet and increasing productivity, schedule a demo with us today!